In the first article we penned for i+s, The Time for Upholstered Fabric Performance in Healthcare Is Now, we provided the history and discovery of coated fabric failures along with the formation of the Durable Coated Fabrics (DCF) Task Group. In 2017, a dozen healthcare interior designers rode the shuttle to Design Connections in Florida, and we learned that we were each experiencing many of the same issues and failures with the fabrics we had specified. In some cases, failures occurred within a few years after installation, but in others it was only a matter of months. These failures included:

- cracking

- crocking and reverse crocking (color transfer)

- stretching/puddling

- stickiness/softening

- peeling/delaminating

- fraying

- staining

- fading or loss of color

Case Study 1: 2019-2020

An Intensive Care Unit (ICU)/CardioVascular and Interventional Radiology (CVIR) waiting area at a community hospital in Maryland was perfect for a field study, pre-pandemic. With approximately 40 metal frame chairs (frames being in good condition), the study of upholstery durability included 18 different fabrics (vinyls, polyurethanes, silicones and thermoplastic elastomers/TPEs) selected from 60 upholstery fabrics. The goals were to:

- To see which fabrics held up best over a six- to 12-month period

- Using a meter to test the bioburden after daily cleaning to see which chairs had the highest and lowest bioburden. [Note: Bioburden is any film that remains on a surface after it is cleaned. It is not necessarily a germ, virus or bacteria; it may simply be ketchup or hand moisturizer that was not cleaned off properly.]

None of the disinfecting chemicals were rinsed off with water as recommended by the fabric manufacturer. Hospital cleaning staff did not have the time or bandwidth to come back after designated kill time to rinse off the disinfectants. While the fabrics in this study held up well (no actual failures, only some puddling on humid days with the polyurethanes), there were three confounding variables that impacted the testing.

The second and third variables included the waiting room was actively being used during the testing and the difficulty of using the biofilm measuring device to collect data as fast as possible. In a busy waiting area, it was difficult to swab and test the chairs quickly. Also, frequently the chair being swabbed and tested was occupied so it would be skipped. Then, once the pandemic hit and patients/families could no longer wait in the waiting room, the study ended.

When the study was halted, there were approximately nine months of data collection and observation of the condition of the coated fabrics. The overall results were that the heavy duty, healthcare (HC), 24/7 fabrics that were selected and recommended by the various manufacturers were a good starting point for evaluation, realizing more consistent study would need to be completed. How these fabrics will hold up over the coming years is yet to be seen.

Even though the study was stopped, the “ah-ha” moment was the realization that there were more complex issues than we had originally identified, which included the types of performance testing currently being completed by manufacturers, labeling inconsistencies and lack of information sharing. Collaboration within our multidisciplinary DCF Task Group helped others realize the depth of the problems and start to develop real-life solutions. Some of the issues included:

- Inconsistent and undefined wording by fabric manufacturers. For example, “heavy duty,” “24/7” and “Healthcare” were used interchangeably with no definition provided.

- Different manufacturers selected different tests (for different durable coated fabrics), creating an assortment of inconsistent testing methods. We created a list of the various tests and found approximately 24 different assessments are typically used by major fabric manufacturers and distributors. However, their memo tags (or sample tags) listed between 0 and 4. Sometimes the manufacturer representatives could provide testing results for several more, but again, there was no consistency even within the same manufacturer.

- Sustainable attributes often superseded durability on the tag. Oftentimes, only sustainable info was listed without any performance information.

- There was no provision for how many tests a product failed when reviewing specification information.

- There was no minimum number of tests that a fabric must pass before it can be called “24/7” or “heavy duty.”

- Test names were inconsistent and confusing:

- Most referenced the Wyzenbeek test; however, various other names were also used, such as the ASTM1 D4157 Wyzenbeek Abrasion Resistance standard.

- (Former) CFFA2–16 (Tear Strength) and AATCC3 16H (Colorfastness)

- ASTM D-751 was sometimes referred to as “Break Strength” and other times called “Seam Slippage. The official name is “Standard Test Method for Coated Fabrics” that includes a whole host of test methods.

- One manufacturer listed 12 staining agents along with result while another supplier listed none.

- Some listed cleaning and disinfection product tests and results on the fabric manufacturer’s website but not on the memo tag.

- Some modified tests were referenced to “improve them,” but testing results could not be compared.

The results of the field study enabled the designers to delve deeper into the issues, and the DCF Task Group discussions continued. More people and organizations began to realize the failures were indeed a very costly issue and were found not only in the US, but in Canada, South America, Europe and Asia. We estimated that the failures were in the hundreds of millions of dollars (including the furniture), and people started listening. These costs were often being absorbed by one or all of the players involved: the client/owner, the fabric manufacturer or distributor, the furniture manufacturer and/or furniture dealership.

Interestingly, the specifier typically was not a participant in the cost sharing for replacing the failed coated fabrics nor were they informed that a product had failed. Not having this information creates the re-specification of a durable coated fabric that could be problematic in a healthcare setting.

Case Study 2: 2017-2018

A new 1.2 million-square-foot, state-of-the-art Cancer Hospital at an Academic Medical Center in Ohio opened in 2014 with LEED Gold and Practice GreenHealth project goals to reduce the use of PVC-based products. As part of the design solution, the design consultant chose to specify 90% of the furniture products with polyurethane-coated upholstery fabrics, wood and polyurethane arm cap finishes. At the time, it appeared this solution would reduce first costs, increase sustainability attributes and have no impact on performance or ease of housekeeping and maintenance. The durability assumption quickly vanished within the first year of operations:

- Within eight months, the Emergency Department waiting areas and exam room fabrics failed.

- Within two years, fabric failures were found in all surgery waiting areas.

- Within three years:

- Gummy texture and peeling of task chairs/stools could be seen in all areas

- White base coating was revealed after the polyurethane topcoat on printed vinyl peeled in clinic waiting areas

- Polyurethane coated wood finishes peeled

- Polyurethane arm caps degraded and split/peeled

Since the Medical Center does not rinse the sanitizing and disinfecting chemicals after application, the fabric warranties were deemed voided by all manufacturers, resulting in an unforeseen financial and operational catastrophe. The Medical Center had to replace contaminated furniture well before expected replacement cycles and created a potentially harmful environment to patients, visitors and staff.

The tests were run on 10 different coated fabric types marketed for “healthcare, 24/7 heavy duty use,” including vinyl, silicone, thermoplastic elastomer and polyurethane with various (or no) topcoats. The tests revealed that some polymers appeared to degrade rapidly when exposed to oxidizing chemicals and daylight, and environmental contaminates were staining and degrading the fabrics.

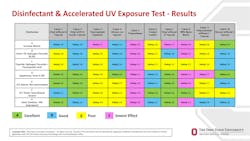

Modified Test #1: Disinfectant & Accelerated UV Exposure Tests, Combined

The fabrics were saturated with various cleaning/disinfecting chemicals and left to dry, then the samples were put in Xenon-Arc chamber to test for lightfastness and degradation for 200 hours. (As above, they were not rinsed off with water because the cleaning staff do not have time to do so. This has been debated and requested by the fabric manufacturers however, it is not going to happen in most hospital settings.)

- UV additive is helpful in preventing damage, but prolonged UV exposure is detrimental.

- Topcoats and performance treatments/base cloth combinations matter—polycarbonate vs. silicone with the same branded performance treatment/topcoat had different results.

- 50% of fabrics rated for healthcare appear vulnerable to alcohol-based hand sanitizer and “non-oxidizing” cleaning chemicals.

- An acrylic topcoat, not usually considered for healthcare, appeared to perform well on the test with disinfecting chemicals—even alcohol-based hand sanitizers.

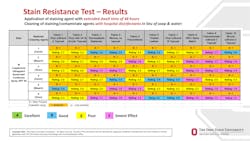

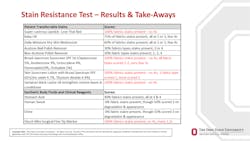

Modified Test #2: Stain Resistance Test

Various common healthcare contaminate staining agents were applied to the fabrics with an extended dwell time of 48 hours (the industry standard is two hours). Eight transferable staining products were used including red lipstick, baby oil, moisturizers, nail polish removers, sunscreens and castor oil-based hair conditioner. Several synthetic body fluids were used as well. After 48 hours, these agents were wiped with common healthcare wipes, the common solution for staff to remove visible stains/debris. The results were dramatic (see charts below).

Conclusion

Our collaboration was beginning to pay off as case studies were identified and testing continued to be developed.

As the Task Group shared more information and as problems and related costs were collaboratively defined and verified, the Chemical Fabrics and Film Association (CFFA) stepped forward and developed a self-certification program that meets CFFA-Healthcare-201 Minimum Performance Standards for Vinyl-Coated and Other Chemical Coated Upholstery Fabrics for healthcare environments. The certification program is for manufacturers and distributors of coated fabrics that meet the CFFA-HC-201, while the certification mark assists specifiers, designers and furniture manufacturers to easily identify appropriate coated fabrics for healthcare environments, which may reduce potential product failures.

The standard requires a coated fabric to pass all 16 tests and includes minimum performance testing requirements. This does not guarantee a fabric will not fail. However, it is a starting point and baseline for durable coated fabric specification, relieving the designer/specifier from gathering baseline testing data and performance criteria for comparison of upholstery options for ultimate upholstery specification for a healthcare project.

There are currently hundreds of durable coated fabrics from many different manufacturers certified to CFFA-HC-201 that have passed all 16 tests. Certified product is available at https://www.cffaperformanceproducts.org/cffa-includes/pdfs/CFFAHC201CertifiedProducts.pdf.

Designers may be familiar with some of the tests; however, there are several that are particularly important for upholstery in healthcare settings (see CFFA Standard Test Methods for specific products and testing requirements):

2. CFFA-100–Accelerated Exposure to Disinfectants. “Purpose: to determine surface changes including color, gloss or surface deterioration, including cracking, peeling or hardening, as a result of exposure to disinfectants” (page 8). This includes Clorox Healthcare Hydrogen Peroxide Cleaner Disinfectant (Wipes), VIREX 256 (diluted to specified concentration) or Clorox Healthcare Bleach Germicidal Wipes.

3. CFFA 142—Stain Resistance in Healthcare Environments. “Purpose: to determine the resistance of the surface of coated fabrics used in healthcare to staining by transferable stains, including body fluids.” Coated fabrics are tested with various stains, including inks from surgical pens, ballpoint pen, as well as from a red lipstick, baby oil, dry skin moisturizer, nail polish remover, sunscreen and castor oil conditioner. Each stain is viewed one hour after cleaning and again after 24 hours (page 24).

While there are other testing recommendations by organizations doing similar tests, it should be noted that each test is voluntary—meaning that a fabric manufacturer can pick and choose which tests they want to complete and are not required to report any testing failures. Additionally, there are no specific requirements for defining and determining if a durable coated fabric is “heavy duty” or for “24/7” use.

It is important to reinforce that the CFFA HC 201 Certification requires a durable coated fabric to pass all tests, and the fabric cannot be certified without passing all 16 tests. Additionally, there is no “CFFA Compliant” fabric. Unless it has the certification mark, there is no verification process to ensure it meets the requirement of the standard and certification guidelines.

Further, other organizations that recommend testing indicate that some of the testing methods and products (such as staining agents) are left up to the designer. But usually, designers do not have the time or money to have testing completed before a fabric is needed for a project. They want to have confidence that the fabric manufacturer has had the testing done. A certified durable coated fabric is the recommended baseline for healthcare upholstery selections and subsequent specifications.

The Certification is a minimum, and there are no guarantees that a fabric will not fail, even if it has passed the CFFA-HC-201. However, it is like getting a driver’s education for your teenage son or daughter. Could they still have an accident even after they have passed the tests? Yes, of course. But wouldn’t you rather ride with someone who has studied for and passed the driving test than someone that hasn’t?

[Note: Part 3 of this series will provide details on the CFFA-HC-201 certification, along with a discussion of some of the test methods and next steps for the Durable Coated Fabrics Task Group.]

About the authors: Barbara A. Dellinger, MA, CHID, FIIDA, EDAC, MDCID, is a principal at Dellinger Consulting LLC; Jane Rohde, AIA, FIIDA, ASID, ACHA, LEED AP BD+C, GGA-EB, GGF, is a principal at JSR Associates; Linda Gabel, CHID, NCIDQ, is a senior planner at The Ohio State University Wexner Medical Center; and Teri Lura Bennett, RN, CHID, CID, IIDA, EDAC, NIHD, is a member of the AAHID Board of Directors and 2022 president.

References:1ASTM: American Society of Testing and Materials.

2CFFA: Chemical Fabrics and Film Association

3American Association of Textile Chemists and Colorists (AATCC)