With election season upon us, politicians of every stripe will yet again make promises to reform our educational system. However, as the Center for Green Schools (CGS)1 has observed, “We’ve spent so much time spinning our wheels over how to fix the who and the what of education, we’ve ignored what needs to be done to fix the where.” The CGS concludes that as public understanding of the impact of facilities on safety, health, education, and communities has grown, forward-looking, sustainable, and affordable solutions are being implemented in our schools across the country.

Evidence of this sea change in the design and construction of our educational facilities is illustrated by a number of statistics:

◗ Construction industry experts predict that by 2025, all new school construction will be green2.

◗ The highest penetration of Leadership in Energy and Environmental Design® (LEED) green building projects is in the education sector3.

◗ The typical green school saves $100,000 per year on operating costs, enough to hire at least one new teacher, buy 200 new computers, or purchase 5,000 textbooks4.

◗ On average, new green schools use 33 percent less energy and 32 percent less water than conventionally constructed schools, significantly reducing utility costs5.

As efforts to improve and green our schools continue to make headway, designers and specifiers need reliable information about products that can help transform them into healthy, sustainable, and safe environments for our children. Considering its visibility, its near-constant usage, and proportionately large percentage of project budgets, it makes sense to start at the floor—and given the numerous benefits and sustainable characteristics of rubber flooring, there’s virtually no smarter choice for schools.

the head of the class

While sustainability and maintenance are critical factors to consider, there are other benefits that rubber flooring can provide that are equally important when it comes to designing effective learning environments. Acoustics, comfort, durability, and safety are all requirements that administrators and facility managers are looking for, and specifying rubber flooring can help meet them. Here’s how:

◗ Sound absorbent. Rubber flooring is impact-resistant, which also gives it noise-abating properties. According to Laboratory Equipment, educators are regularly challenged by a variety of sound-related factors as they are engaged in lessons or lectures to students, including: reverberation; echoes; noise associated with weather, traffic construction, and road maintenance outside the building; the distractions of foot traffic; doors opening and closing; and classroom noises associated with heating, ventilation, and air-conditioning systems, computers and students’ voices. In fact, up to 70 percent of unwanted noise and as much as 17 decibels of sound can be reduced simply by specifying rubber flooring, which helps to reduce distractions in learning environments—a clear benefit to both teachers and students6.

PageBreak◗ Ergonomic. Standing on hard floors all day can cause strain on the back and joints—even with comfortable footwear. Thanks to its flexibility and tensile strength, rubber is a much more comfortable surface to walk and to stand on than other resilient options and can help reduce fatigue on feet, legs, and backs, which is important to teachers and instructors who spend long periods of time on their feet7, as well as to athletes who are training or playing sports.

◗ Durability. Rubber flooring is resistant to scuffing and scratching, and can withstand years of foot traffic without showing wear and tear. It can also be infused with performance compounds making them highly resistant to petroleum oils, bacteria, and fire. Rubber floors are water resistant and will not warp or bend like other flooring products can.

◗ Slip resistance. Floors and flooring materials contribute directly to more than 2 million fall injuries each year, and slips and falls account for over 1 million emergency room visits, or 12 percent of total falls8. Rubber floors offer inherent traction that help create a safe, slip-resistant surface for stairs and floors that are accustomed to wetness. Additionally, some rubber flooring products feature a raised design that allows liquids to be safely channeled off the walking surface, providing excellent moisture drainage, thereby enhancing slip resistance—an important safety feature to consider in school buildings.

types of rubber flooring

To the uninitiated, rubber flooring may look the same on the surface, but not all products are created equal. In fact, there are different types of rubber flooring products manufactured for specific functions that have applications across a variety of educational facilities. Following are a few of them:

ESD (Electro Static Dissipative) Rubber—These specially formulated tiles dissipate static electricity in areas where explosive elements are used (such as chemistry labs) and static electricity presents a hazard (such as in server rooms or computer labs), while helping to control static charges created by the human body. Installing ESD rubber flooring tiles with specially formulated conductive adhesive creates a continuous conductive pathway for static charges to flow to the ground point. The conductive flooring system attacks voltage generation at the source, the floor-shoe or floor-caster interface. When used in conjunction with static control footwear and wrist straps, ESD rubber flooring provides greater mobility in the area. It is ideal in areas requiring a solution for unwanted Human Body Voltage (HBV) with a high level of personnel traffic.

Sports Flooring/Crumb Rubber—Combines the durability of vulcanized post-consumer recycled tire material from commercial and automobile tire compositions mixed with vulcanized post-industrial recycled and colored rubber chips which are then encapsulated in a premium urethane binder creating very tough and durable flooring. The crumb rubber material along with the colored chips are bonded together with a premium urethane binder that creates a non-porous product that will not absorb liquids and allows for easy removal of spills and unwanted debris. Designed specifically for indoor or outdoor commercial, residential, industrial, and fitness applications; it can also be used for play areas in schools, fitness centers/weight rooms/gyms, daycares, ramps, locker rooms, cardio areas, ice arenas, and retail flooring.

Smooth or Profiled Rubber Tile—This product is a resilient and typically homogeneous rubber tile, which can be heterogeneous with the addition of colored chips or cork to increase the visual texture, while providing excellent resistance to abrasion, chipping, cracking, and permanent indentations, and yet provides fast and economical installation. Rubber tile designs are available in solid or marble colors that make it a great choice where aesthetics are a concern (and when are they not?). Rubber tiles easily coordinate with other flooring products and can be mixed and matched with tile, treads, wall base, and accessories. It is great for use in the classroom or other public areas.

Entry Tiles—Made for the most demanding applications, rubber entry tiles are durable, anti-slip flooring products with outstanding sound absorption properties. This product is ideal for use as a walk-off mat for entryways, lobbies, concourses, and foyers in schools, theaters, gymnasiums, and other demanding indoor and outdoor applications. This product is often available in durable, non-vulcanized and vulcanized versions. Non-vulcanized entry tiles are often constructed of strips from a biased ply truck tire that are bonded to a spunbond polyester backing and then buffed to reveal the cord of the tire.

Rubber wall base—Designed for use in commercial and residential wall base applications, thermoset (TS) rubber wall base products are a PVC-free alternative to their vinyl or rubber/vinyl blended counterparts. Thermoset rubber wall base occurs in a process known as vulcanization, which processes the compound with heat, steam, and pressure to set the molecular structure therefore making it extremely durable and resistant to change when exposed to extreme heat or cold climates. These products are highly durable and extremely flexible, allowing for easy installations around columns, corners, and architectural curves without product acclimation.

When it comes to choosing which flooring product to use in a given application, designers and specifiers should make selections based on its intended use in the educational facility. The degree of thickness and load level that the floor can handle will vary greatly depending upon whether it is intended for use as a sports floor in a gymnasium, a weight room, or as a heavily-trafficked entry or hallway, for example. Industry-accepted codes and standards on resilient flooring products—including sheet, tile, treads, and bases—can help ensure specifiers are choosing the right surface for the application.

PageBreakFor example, ASTM developed the F1344-15 Standard specification for Rubber Floor Tiles in 1991, which replaced the old Federal Specification #SS-T-312b. These standards provide dimensional and performance criteria for product acceptability. The ASTM F1344-15 standard:

◗ Permits a thickness tolerance of + .015”/- .005” for pattern tile and +/- .005” for smooth tile.

◗ Permits a hardness rating not less than 85 when tested in accordance with ASTM D-2240 Durometer (hardness).

◗ Provides performance requirements in the areas of static load limit, resistance to short-term chemical resistance, resistance to heat, and abrasion resistance.

For athletic applications, on the other hand, specifiers should refer to the ASTM F2772-11 standard that governs athletic properties for indoor sports floor systems. In order to meet the requirements of this standard, a floor must maintain:

◗ 10 percent minimum shock absorption

◗ less than 3.5 mm (0.13 in.) vertical deformation

◗ minimum 90 percent ball rebound

◗ between eight and 110 sliding effect value

These standards are required to meet existing codes and are excellent guides in selecting the right flooring, but specifiers must also weigh a myriad of other considerations including durability, acoustics, aesthetics, and of course, maintenance, to ensure an educational facility is properly outfitted with the most appropriate product.

maintenance: a no-brainer

If the low lifecycle costs of rubber are the number one reason specifiers prefer rubber flooring over the alternatives, then its low maintenance isn’t far behind on the list of benefits. The fact is rubber flooring is inherently easy to maintain, making it an excellent choice for school buildings. Some manufacturers recommend a floor finish where a high-gloss is desired, but it is not required because most rubber floors can be buffed to a nice luster. Day-to-day cleaning typically consists of a neutral cleaner, such as soap and water, which contributes to its overall low lifecycle costs. Regular cleaning with an auto scrubber will bring out rubber’s natural sheen, through a technique commonly referred to as burnishing, without the need for stripping and waxing. When combined with its inherent resistance to damage, rubber floors are far more likely to go out of style well before they wear out.

Because rubber flooring does not require waxing or specialty coatings, it eliminates the need for labor-intensive stripping and re-coating, which saves money on fewer cleaning products and reduced labor hours. Additionally, the absence of fumes associated with harsh cleaning products, waxes and sealants contributes to improved indoor air quality and reduces opportunities for interference with classes and administrative operations, according to Laboratory Equipment.

To summarize, what makes rubber flooring a no-brainer in terms of maintenance are the following characteristics:

◗ Easy to maintain

◗ No stripping or re-coating required

◗ No harsh chemicals required

◗ No wax required a smart and sustainable alternative

In high-traffic, high-use applications such as K-12 or higher education environments, there are a number of resilient flooring options from which to choose—each with pros and cons ranging from cost, performance, and sustainable characteristics. Today, rubber flooring is the number one alternative to PVC flooring apart from linoleum9.

There are a number of reasons for rubber’s popularity as a flooring option, not only in the education sector, but also in healthcare and institutional markets as well—and its sustainable characteristics are among the main factors. While most of today’s rubber flooring contains synthetic materials, manufacturers can create rubber tiles that are partially compounded using natural rubber, which is a renewable raw material extracted from the sap of the tropical rubber plant. Some rubber tiles are manufactured using post-consumer recycled tires. And no-wax rubber floors reduce harmful refinishing chemicals into the environment, and require less water usage to maintain.

In school environments, air quality is a major concern that may be affected by emissions from the flooring material itself, as well as from the adhesives used to install the floor and surface coatings and maintenance materials like wax and strippers. Insufficient cleaning or excessive use of harsh cleaning chemicals, and other maintenance issues can trigger a host of health problems—including asthma and allergies—that increase absenteeism and reduce academic performance10.

Research links key environmental factors to health outcomes and students’ ability to perform. Improvements in school environmental quality can enhance academic performance, as well as teacher and staff productivity and retention11.

Additionally, by specifying rubber flooring, architects and designers are making a choice that can contribute to LEED points under the new v4 rating system. Many rubber flooring products qualify for credits in the Materials and Resources (MR) and Indoor Environmental Quality (EQ) categories, and depending upon the location of the project, points may be earned for regional manufacturing. Low VOC emissions have also been documented through third-party testing of U.S. rubber flooring products. The measured emissions have been below the most stringent U.S. health standards12. Rubber flooring manufacturers in the U.S. are focused on further reducing chemicals in rubber products for the health of their employees and end users alike. Further, as more schools are being designed to earn a CHIPS (Collaborative for High Performance Schools) rating, rubber flooring can also help make schools energy, water, and material efficient, well-lit, thermally comfortable, acoustically sound, safe, healthy, and easy to operate.

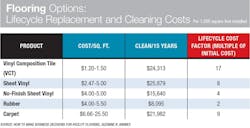

Rubber flooring’s most attractive feature to specifiers, however, is its lifetime maintenance cost—the lowest of all major flooring options (see sidebar below). Rubber has been proven by several studies to be one of the most cost-efficient selections for flooring installations. Compared to other resilient flooring products, its lifetime costs are significantly less than the alternatives, and when combined with its durability, performance, and aesthetics, this makes it a perfect solution for educational environments.

Finally, rubber flooring has an average lifecycle of 30+ years, reducing the need for frequent removal and disposal of the product and conserving natural resources in the process. It’s also one of the reasons it often replaces or is specified over VCT, vinyl sheet goods, and linoleum.

To recap, rubber flooring possesses any or all of these sustainable features, including:

◗ Long lifecycle

◗ Recycled content

◗ Low VOCs

◗ Renewable material

◗ Recyclable

But rubber flooring isn’t all about performance and environmental benefits. With advancements in technology, rubber flooring also offers aesthetic appeal that is second-to-none. Today, specifiers today have a wide variety of colors, patterns, and textures from which to choose, making flooring specification for schools and universities a breeze.

When you do the math, resilient rubber flooring is truly a smart choice for educational environments.

About the Author

Robert Nieminen

Chief Content Director

Chief Content Director, Architectural Products, BUILDINGS, and interiors+sources

Robert Nieminen is the Chief Content Director of three leading B2B publications serving the commercial architecture and design industries: Architectural Products, BUILDINGS, and interiors+sources. With a career rooted in editorial excellence and a passion for storytelling, Robert oversees a diverse content portfolio that spans award-winning feature articles, strategic podcast programming, and digital media initiatives aimed at empowering design professionals, facility managers, and commercial building stakeholders.

He is the host of the I Hear Design podcast and curates the Smart Buildings Technology Report, bringing thought leadership to the forefront of innovation in built environments. Robert leads editorial and creative direction for multiple industry award programs—including the Elev8 Design Awards and Product Innovation Awards—and is a recognized voice in sustainability, smart technology integration, and forward-thinking design.

Known for his sharp editorial vision and data-informed strategies, Robert focuses on audience growth, engagement, and content monetization, leveraging AI tools and SEO-driven insights to future-proof B2B publishing.