Sustainable Benefits of Underfloor Service Distribution

By Bill Reynolds

Take a look at the construction business in any U.S. city and you'll see a common theme emerging: sustainable building. It is much more than a trend. It's an approach toward building and renovation that seeks to proactively address energy efficiency and material resource use with design and construction innovations.

In fact, the U.S. Green Building Council (USGBC) cites that green building construction is expected to exceed $12 billion this year.

If you are talking green, part of the conversation must always be about salvaging old buildings, as well as constructing new, more eco-friendly ones. Yet, one of the biggest challenges in renovating older buildings is adding services within the confines of the existing structure. The slab-to-slab heights are often limiting and in many cases can preclude using the building for new business environments, HVAC, and telecommunication services. Some of the biggest challenges arise when architects and designers attempt to retrofit HVAC services, as many older buildings do not have sufficient floor-to-ceiling clearances to accommodate traditional overhead HVAC ductwork. If an overhead HVAC system already exists but is at the end of its life-cycle, its location and footprint may complicate the introduction of a new system.

When we think about basic services such as HVAC and wiring and cable, we instinctively look up to find ductwork or over to find electrical outlets and computer cables at fixed locations on the walls. But what about looking down to raised access floors to satisfy all of these needs?

To recycle existing buildings, as well as maximize floor-to-ceiling heights in both old and new structure designs, buildings professionals are using access floors for their sustainable advantages and design options for both types of building projects.

What is an Access Floor?

An access floor is a raised system comprising an understructure and welded steel floor panels filled with lightweight cement. The understructure provides positive positioning and lateral retention, ensuring that the floor is soundly supported on all contact points. The 24-inch-square floor panels use typical finished floor heights from 2½ inches up to 36 inches on understructure that can also offer a height adjustment leveling device to ensure the floor is level even when the slab is not.

The resulting underfloor pathway created by the raised floor panels provides housing for any type of service distribution system, modular wiring, passive or active zone cabling, and HVAC service. To achieve this, the modular panels that make up the access floor can be equipped with PVD (power-voice-data) termination boxes to provide convenient, flexible access to all of these services. Plus, the PVD boxes can be relocated anywhere the tenant desires as spatial layout or telecommunications needs change. Modular and relocatable VAV (variable air volume) air diffuser terminals or passive air diffusers provide increased occupant comfort and individual control of air volume.

Floor strengths can vary to accommodate a variety of loading environments within a building, from workstation environments and data and print room spaces to heavily trafficked service corridors and elevator lobbies. Like traditional flooring, access floors also offer a variety of finishes - from luxury vinyls to woods, cork, rubber, and terrazzo. Traditional high-pressure laminates, static control vinyls, freelay carpet, and hard tile finishes are also available to create a unique and coordinated look. Essentially, access floors look, feel, and function similar to traditional floors, but what lies beneath offers far more sustainable advantages.

Underfloor Air Service

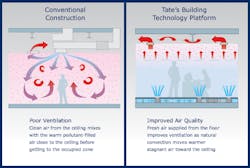

Hot air rises, yet conventional HVAC systems are designed to distribute cool air from the ceiling. By supplying cool air at very low pressure from an access floor using natural convection and warmer supply air temperatures, HVAC energy costs can be reduced by 20 percent or more. How can this be accomplished?

Using the space under the access floor for air distribution requires minimal ducting because the entire space is used as the service plenum to provide fresh air, which it delivers from below, directly to the 6-foot occupied zone. As the fresh air enters the zone, it replaces existing contaminated air rather than diluting it. Pollutants and stale air in the zone are carried to the ceiling by natural convection and removed through return outlets. Because the air pathway is situated under the access floor, users can easily adjust air direction and volume for their individual comfort through modular floor-mounted diffusers. Underfloor air distribution (UFAD) systems save money at initial installation and throughout operation compared to overhead systems by speeding installation time, eliminating costly, rigid overhead ductwork, and reducing fan energy use by an average of 40 percent. The static pressure required for an underfloor air distribution system is .05- to .10-inch wg, which represents approximately one-third of the pressure required for an overhead system. In turn, this reduces overall energy consumption by at least 20 percent.

Not only is underfloor air distribution a cost-effective alternative to traditional overhead systems, but it has also been proven to provide equal or better air distribution. Experiments conducted by the Center for the Built Environment at the University of California, Berkeley, found pressurized plenums with as little as 3 inches of space can maintain uniform distribution of airflow to diffusers in a 3,200-square-foot area. (Typical heights for underfloor air distribution are 10 to 18 inches.) Add to this the natural appeal of individual occupant airflow control and the overall personal comfort advantages are pretty clear.

ALL PHOTOS, RENDERINGS TATE ACCESS FLOORS INC

Conventional HVAC construction requires a large ceiling void for fixed service pathways. This often requires creating a ceiling void to accommodate the system. Using underfloor service distribution eliminates the need for this additional overhead space, which can reduce initial building material costs. New buildings can also achieve a 5 to 10 percent reduction in slab-to-slab heights, resulting in materials savings, construction cost reductions, and faster construction rates. The access floor also supplies a much greater degree of flexibility and adaptability to the changing needs of a building's inhabitants, as diffusers and standard panels can be reconfigured to provide air to any location the owner or the occupant desires.

Diffusers used in access floors may include VAV terminals with built-in volume control dampers that automatically adjust to accommodate the thermostat setting and occupant comfort levels. Passive diffusers feature manually adjusted dampers, allowing occupants to adjust volume and direction. Because everything is modular, in-house facility personnel can also easily change out diffuser locations, as all panels are interchangeable with one another.

Wire and Cable Services

Mirroring the flexibility of underfloor air distribution, underfloor wire and cable distribution comprising modular plug-and-play zone wiring and cabling provides the flexibility to respond to equipment layout and technology changes quickly and easily and with almost no wasted materials. Power, data, audio, and video all are contained in floor-mounted modules, which can be positioned within the access floor wherever those services are needed.

Comparatively, traditional wiring and cabling outlets fixed in walls and columns are fundamentally inflexible and make reconfiguration expensive, disruptive, and wasteful. With these hard-wired systems, existing wires are typically abandoned and new wires are run to service a new configuration. This is expensive and wasteful. Moving people and furniture or making additions and changes to technology become costly in this type of environment. Add to this the burden of running wiring and cabling into ceiling pathways and reconfiguration becomes severely limited. Ceiling pathways also increase vertical run lengths, labor, and suspension material costs and make subsequent changes disruptive and expensive. Fixed, poke-through options for wire and cable delivery can also cause disruption and security issues with occupants both above and below.

Access floors, on the other hand, eliminate the need to embed wiring and cabling within concealed, rigid structures such as walls, columns, and ceiling pathways. Instead, they comprise modular plug-and-play wires and cables, which can be reused continually no matter how often reconfiguration occurs. This allows occupants the freedom to access and/or move wiring and cabling services quickly and easily by simply removing the panel that contains the PVD termination boxes. An access floor also provides admittance to the service pathway at any location on the floor plate. Without the need for nonstructural columns to hide wiring, underfloor wire and cable service also provides the architect more design choices. The natural result of these design freedoms is greater flexibility and a more pleasant indoor environment.

A Better Work Environment

The World Health Organization states that most of a person's daily exposure to many air pollutants comes through inhalation of indoor air. This, coupled with the large amount of time people spend indoors, has contributed to the significance of indoor air and overall environmental quality. Factors such as low-emitting materials, controllability of HVAC systems and thermal comfort, lighting quality, acoustics, and access to views are just some of the issues that can enhance our indoor environments. Ultimately, accommodating occupant preferences is a key characteristic of happy, healthy work environments and one that access floors and underfloor service distribution effectively address.

For example, indoor air quality is optimized through improved ventilation and less mixing with airborne pollutants. In addition, the floor-mounted services reduce overhead ceiling space requirements, increasing daylighting opportunities and improving acoustics with low-pressure, underfloor HVAC distribution. Finally, personal control of air direction, volume, and location of air diffusers improves the thermal comfort and reduces hot/cold complaints from occupants. As a result, work environments that meet the needs of employees pay off with increased productivity and decreased absenteeism.

LEED Certification

Every building is comprised of many manufactured and processed materials, each of which make up a building's embodied energy. The embodied energy of a building increases over its lifetime because it represents the energy consumed by all of the processes associated with its construction and maintenance. The best way to reduce embodied energy is to design flexible, adaptable, sustainable buildings.

As the influence of the USGBC grows, the LEED program is transforming the marketplace by increasing recognition and value of high-performance buildings. In the United States, buildings consume approximately 37 percent of the energy and 68 percent of the electricity produced annually, according to the U.S. Department of Energy. These statistics make the Energy & Atmosphere category an essential part of LEED certification. Evaluating a building's energy load and using methods such as access floors to afford daylighting and efficient HVAC systems in the design can earn points toward LEED certification.

Many LEED-certified buildings use underfloor service distribution technologies, not only for the sustainable benefits already described but also because the access floor components themselves are manufactured using recycled materials. Most use more than 30 percent recycled materials that, when combined with regional manufacturing in many parts of the United States, contribute points toward LEED.

Choosing the proper building materials that make up the access floor is just as important as the sustainable opportunities the access floor provides due to the environmental impact associated with installation, processing, and transportation of the materials. Reusing existing building materials is one of many effective ways to reduce environmental impact. It's important to remember that taking advantage of recycled material content and locally manufactured materials can also contribute to sustainability.

First-Build and Operating Cost Savings

A common misconception about sustainable building and renovating is that the cost outweighs the environmental benefit. Some underfloor service distribution projects have reported reductions of up to 10 percent in first-build construction costs. Here are some examples of how access floors achieve these savings:

- Voice and Data Cabling - Reduce cable run lengths, eliminate cable trays, and lower labor costs for installation

- Power Wiring - Plug-and-play technology significantly reduces installation costs

- Furniture - Eliminates dependency on costly systems furniture

- Air Distribution - Significantly reduces trunk, branch, and discharge ductwork

- Ceiling - Reduces or potentially eliminates suspended ceiling requirements

- Slab-to-Slab Height - Can be reduced in new construction projects, speeding up build times

- Tax Benefits - Underfloor components qualify for accelerated depreciation as personal, tangible property

- Time-to-Occupancy - Access floors and underfloor services install quickly, allowing for occupation sooner

After any initial capital investment in access floors, their energy-efficient design and long-term flexibility provide operational benefits well beyond the installation. For example, lower fan power, extended use of the economizer, and thermal stratification save an average of 20 percent in energy costs. Moreover, regarding workstation churn, underfloor service distribution can reduce turnover costs and employee relocation by up to 50 percent by reusing existing floor-mounted components and modular wire and cable in new configurations. Finally, underfloor components may be considered personal, tangible property, and therefore qualify for accelerated depreciation tax benefits over a period of 6 years versus the traditional 40-year period.

A Sustainable Solution

Designing and constructing new buildings or renovating existing ones carries with it significant responsibilities to both the occupants of the building and to the surrounding environment it inhabits. From an environmental perspective, using access floors with underfloor service distribution of air, wire, and cable service reduces the amount of building materials required, including ductwork, cable trays, ceiling tiles, horizontal and vertical feeds, powered furniture, and façade materials.

The key to cost-effective green design is to think holistically early in the design process. A well-designed building using access floors and underfloor service distribution enhances the structure's sustainability by improving indoor environmental and air quality, providing modular flexibility for reuse and relocation of existing resources, and reducing materials resources in construction, operation, and maintenance over the life of the structure.

Bill Reynolds ([email protected]) is director of marketing at Tate Access Floors Inc.

References:

Under Floor Air Technology, Center for the Built Environment, June 7, 2007

Energy Efficiency and Renewable Energy, U.S. Department of Energy, June 7, 2007

Green Building by the Numbers, U.S. Green Building Council, June 7, 2007

ARCHI-TECH welcomes comments on the distance education program, including its content, format, and process for AIA/CES learners.

Please contact Maureen Patterson at (319) 364-6167 or [email protected].

Stamats Buildings Media, publisher of ARCHI-TECH, is the provider of ARCHI-TECH'S AIA/CES distance education programs. Stamats Buildings Media's provider number is J683.