Providing 'Green' Solutions with Geothermal Applications

By Xiaobing Liu, Ph.D.

Geothermal heat pump systems use the natural thermal properties of the earth to maintain the temperature of the heat pump water loop, completely eliminating the boiler and heat rejector. They are recognized as the most energy-efficient and environmentally friendly HVAC systems generally available by the U.S. Department of Energy (DOE) and Environmental Protection Agency (EPA). Geothermal heat pump systems provide all the benefits of a water loop heat pump system and many more:

- Eliminate boiler and heat rejector installation, operation, and maintenance costs

- Eliminate all outdoor equipment and any related concerns over architectural aesthetics, radiated sound, freeze protection, legionella, or vandalism

- Eliminate the water loop temperature controls and associated panels, control valves, switches, and sensors

- Reduce mechanical room space to just the pumping aspects

- Increase energy efficiency by using renewable energy for loop temperature conditioning and by providing more favorable water temperatures to the heat pumps throughout the year

- Allow water-source heat pump systems to be economically scaled down to applications as small as a single zone

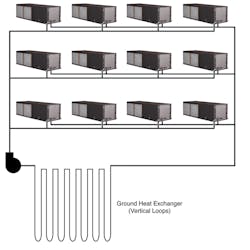

Ground Loop Heat Pump Systems

Ground loop systems use water (and in some cases antifreeze) circulating through a closed subsurface piping loop that functions as a heat exchanger with the surrounding earth. The subsurface piping loop, or ground heat exchanger, may be placed in horizontal trenches, or more commonly for commercial systems, in vertical bores. The ground heat exchanger is essentially an extension of the heat pump water loop, sized so it will passively maintain the circulating loop water temperature within an acceptable temperature range of 30 to 95 degrees Fahrenheit (-1 to 35 degrees Celsius).

Ground heat exchanger sizing is usually determined using computer software and is based upon building loads, local climatic conditions, and site-specific soil thermal properties. They are typically constructed of high-density polyethylene (HDPE) pipe, with life expectancies exceeding 50 years. All underground joints are thermally fused and provide a finished product that is stronger than the pipe itself.

Horizontal heat exchangers are typically buried from 3 to 6 feet deep (1 to 2 meters), requiring from 1,000 to 2,000 square feet of land area per ton of block building load (30 to 60 square meters per kilowatt). They are installed in large open areas such as athletic fields and parking lots. Although cost-effective to install, the land area required limits the applications for horizontal loop systems.

Vertical heat exchangers are installed in drilled boreholes, usually from 150 to 300 feet deep (50 to 100 meters), requiring from 100 to 300 square feet of land area per ton of block building load (3 to 9 square meters per kilowatt). The borehole diameter is normally from 4 to 6 inches (10 to 15 centimeters). Vertical heat exchangers are installed in landscape and parking areas and even under the building. They are the most common ground heat exchanger for commercial applications.

Surface-Water Heat Pump Systems

Surface-water systems use a heat exchanger that is submerged within a body of surface water. The usual applications are ponds or lakes. The heat exchanger is constructed of coils of HDPE pipe or, less commonly, nonferrous metal plates or coils. As with ground loop systems, surface-water heat exchangers are in essence extensions of the heat pump closed water loop.

Surface-water heat exchangers generally require a body of water with a minimum depth of 10 feet (3 meters) and minimum surface area of 400 square feet per ton of block building load (11 square meters per kilowatt). For heating dominated loads in cold climates the required surface area may be larger. For cooling dominated loads, the addition of spray fountains may reduce these requirements. Sizing of the heat exchanger and determination of the minimum water body requirements is usually performed with computer software and is based upon building loads, local climatic conditions, and site-specifics. On projects where a body of water is accessible or where one can be economically created (as from a storm water detention area), a surface-water system is usually the most cost-effective geothermal design.

Groundwater Heat Pump Systems

Groundwater systems use water pumped from a well as the thermal energy source/sink for a water-source heat pump system. Groundwater remains at a constant ideal temperature for heat pumps throughout the year, generally between 40 and 80 degrees Fahrenheit (5 and 25 degrees Celsius) depending on geographic location. The discharge water can be drained into a surface water body or returned to the aquifer via an injection well. There are occasional secondary uses, such as irrigation, for discharge water.

There are several methods of installing groundwater systems and many considerations that factor into an optimal design. Principal are water quantity, quality, and depth, water discharge options, local geology, total system size, and code requirements. Where applicable, groundwater heat pump systems can be cost-effective to install and require minimal land space. Typical system configurations are:

- Open System

Groundwater is directly pumped through each zone heat pump and then discharged. Flow to each heat pump is typically controlled by a two-way valve. Although simple and cost-effective to install, the energy sharing benefits of a closed water loop are lost because the water is directly discharged after use. In addition, the piping system and all zone heat pumps are subject to scaling and other water quality-related issues. As such, open systems are generally limited to buildings using a small number of zone heat pumps. - Closed Loop with Heat Exchanger

Heat exchanger systems combine water-source heat pumps on a common piping loop with an isolating heat exchanger (usually plate type) that uses groundwater to maintain the circulating water temperature within a controlled range. They retain the energy sharing benefits of the closed water loop, minimizing the demand for groundwater. In addition, scaling and water quality issues are limited to the plate heat exchanger, which can be readily cleaned, reducing maintenance costs and extending system life. The use of an isolating heat exchanger makes groundwater systems practical in large-scale buildings with many zones. Heat exchanger systems are applicable to standard water wells or standing column wells. They have also been successfully used with surface water sources, including seawater. - Standing Column

Standing column wells are semiclosed systems that return most of the heat pump discharge water back to the supply well. The well is specially designed to combine direct ground heat exchange with a limited amount of groundwater use. A single standing column well is typically from 500 to 1,500 feet in depth (150 to 450 meters), and at maximum length can support up to 30 tons of block building load (105 kilowatts). From 80 to 90 percent of the supply water flow is returned to the standing column well with the remainder discharged by other means. This return flow reduces the required aquifer production capacity. The portion of supply flow that is discharged brings "fresh" groundwater flow toward the well, limiting well supply water temperature extremes. Being semiopen, the systems remain subject to scaling and other water quality-related issues, unless combined with an isolating heat exchanger as described above.

ALL IMAGES CLIMATEMASTER

Hybrid Geothermal Systems

Hybrid designs blend the use of geothermal resources and conventional heat rejectors to provide a highly efficient and cost-effective system. They take advantage of the fact that building heating and cooling loads are generally not balanced, with cooling being dominant in most cases due to internal gains. Rather than upsize the ground heat exchanger to meet the higher cooling load, it is sized to meet the heating load, and a heat rejector is added to the system.

Hybrid systems still eliminate the boiler and the use of fossil fuels while at the same time reducing the land area and first costs required to install the ground heat exchanger. The reduction in ground heat exchanger size can be more than what the difference in loads might imply. When annual loads are imbalanced in systems with dense ground heat exchanger arrays, there are long-term thermal buildup effects. Geothermal design algorithms compensate for this by increasing the ground heat exchanger size. A properly engineered hybrid system can remove both the difference in loads and the long-term effects from the ground heat exchanger sizing calculation.

When water loop heat pump systems were introduced into the marketplace, most engineering guides recommended the addition of thermal storage to the water loop. Decades of low energy costs gradually diminished the use of added storage. The ground heat exchanger of a hybrid system provides the benefits of a massive thermal storage capacity, in addition to a source of renewable energy. This provides more favorable loop water temperatures to the zone heat pumps, further improving system efficiencies.

Geothermal Heat Pump System Design

Major advances have been made recently in sizing ground loop (geothermal) systems. ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) and IGSHPA (International Ground Source Heat Pump Association) have published design manuals for many years. Consulting engineers have used loop-sizing software (without building load calculation function) for quite some time as well. The latest improvement in ground loop simulation is built into the latest version of eQUEST, a quick energy simulation software. DOE-2 (DOE is the U.S. Department of Energy), the simulation engine of eQUEST, uses a successive algorithm to simulate the whole building and the associated HVAC system. DOE-2 was developed as a "generic" (i.e. nonHVAC manufacturer-specific) energy simulation engine that can be built into a customized user interface. The latest version of eQUEST includes add-on features for selecting heat pumps and additional borehole field configuration choices.

The latest version of eQUEST includes an integrated building and HVAC hourly simulation program resulting from continuous development and enhancement for more than 25 years. Primary support of the development has been from the U.S. DOE and U.S. electric and gas utilities. Graphical and detailed text reports provide summaries for items such as building loads, energy use, and life-cycle costs. Once the building is modeled, a g-function based model is used for hourly simulation of the ground loop heat exchanger. Within that model, a sophisticated model has been adopted to calculate borehole thermal resistance. Thermal properties of various antifreeze aqueous solutions are calculated and used in the calculation of borehole thermal resistance.

G-function is an algorithm proposed by Dr. Per Eskilson, Ph.D. (1987), at Lund University of Sweden, for fast calculation of borehole wall temperature. Eskilson calculated the temperature distribution around a borehole using two-dimensional transient finite-difference equations on a radial-axial coordinate system for a single borehole in homogeneous ground with constant initial and boundary conditions. The temperature fields from a single borehole were superimposed in space to obtain the response from a borehole field of several boreholes in certain arrangements. The temperature response of the borehole field was converted to a set of nondimensional temperature response factors, called g-function. The g-function represents temperature change at the borehole wall over certain time duration in response to a step heat pulse. Once the response of the borehole wall temperature to a single step heat pulse is represented with a g-function, devolving the heat rejection extraction profile into a series of step heat pulses and superimposing the response to each step heat pulse can determine the response to any arbitrary heat rejection/extraction profile.

A user-friendly interface for specifying GHX (Ground Loop Heat Exchanger) has been developed and integrated in the design wizard of eQUEST. Parameters associated with the GHX are categorized into four sections in the interface. The first section is for specifying the circulation loop, including pump configuration, flow control, design loop temperatures, etc. The second section is for specifying ground and thermal grout properties as well as years of previous operation of GHX. Thermal conductivity and diffusivity of various types of soil/rock and thermal conductivity of various commonly used grouting materials are provided in built-in databases. Users can either select rock/soil and grout type from the databases or input the thermal properties directly. The third section is for specifying parameters of boreholes, including GHX type, configuration, geometry, pipe material, and size. More than 300 different vertical GHX configurations are available, including boreholes in a straight line, in the form of L- or U-shaped lines, and as open or filled rectangles. The fourth section is for specifying properties of the fluid circulating through the GHX. In addition to pure water, aqueous solutions with different concentration of antifreezes can be selected. Detailed online help, databases, and design tips for each of the required parameters can be accessed in the user interface.

Geothermal heat pump system design has evolved to the point where it is no more difficult to design than a water loop heat pump (boiler/tower) system or any other HVAC technology. Today's sophisticated but easy-to-use software provides a powerful tool for optimal ground loop heat exchanger design and therefore achieves cost-effective geothermal heat pump systems.

Dr. Xiaobing Liu ([email protected]) is systems engineering manager at ClimateMaster Inc. in Oklahoma City. He received his doctorate in mechanical engineering from Oklahoma State University in 2005. Liu also has several years of practical experience working in large consulting engineering firms in China, where he designed and supervised the commissioning of HVAC systems. He is a member of ASHRAE technical committee 6.8 (Geothermal Energy Utilization) and 9.4 (Applied Heat Pump/Heat Recovery Systems).

ARCHI-TECH welcomes comments on the distance education program, including its content, format, and process for AIA/CES learners.

Please contact Maureen Patterson at (319) 364-6167 or [email protected].

Stamats Buildings Media, publisher of ARCHI-TECH, is the provider of ARCHI-TECH'S AIA/CES distance education programs. Stamats Buildings Media's provider number is J683.